|

SIPTube®

Valve The SIPTube® valve can

reach deep into your process to add or withdraw material, yet can be

re-cleaned and re-sterilized at any time. |

|

|

Now

there is a solution for stagnation and grow-back problems that are due to

an inability to re-clean and re-sterilize throughout a production run.

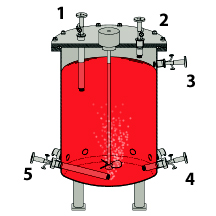

The SIPTube®

valve can replace

five traditional devices found in tanks and process pipelines: (1) dip

tube, (2) gas sparger, (3) addition device, (4) headspace feed device and

(5) fed-batch withdraw/return device.

|

|

|

|

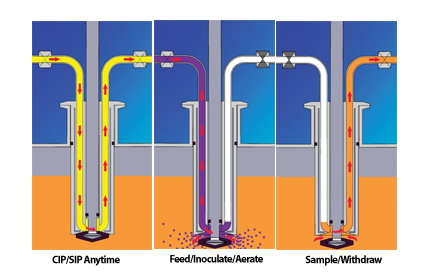

The SIPTube® valve features a deep U-shaped passage

with the valve seal located at the tip, adjacent to the process interface,

so that the device that can be completely cleaned and sterilized anytime you like, not just at the beginning of your

process. In contrast, other sterile access port assemblies typically consist of valve seals located outside the tank or pipeline, together with a section of blind tube extending into the process. This creates a deadspace that cannot be cleaned or sterilized once your process

begins. |

Read more about it

Don't have the

Adobe Acrobat Reader?

Click

here. |

| |

|

|

The SIPTube® valve's deep "U" passage design defines a complete cleaning and sterilizing flow path - from the inlet down to the valve seal tip and back up to the outlet. The passage arrangement also creates a vortex flow pattern that effectively scours the valve chamber, and expels condensate.

Optional valve body insulation inhibits heat transfer during steam sterilization, allowing you to safely sterilize-in-place anytime you like, even with the most heat-sensitive processes.

More...

The elongated, probe-like body of the SIPTube® valve easily retrofits in minutes into standard tank and process line ports. It can reach deep into the process to deliver material or capture truly representative samples.

In-process clean-thru/steam-thru capability offers numerous advantages:

| By eliminating loss of flow due to clogging that often occurs with traditional devices, the

SIPTube® valve improves process control for gases and metered feeds. |

| When multiple SIPTube® valves are installed, one unit can be cleaned and sterilized while the other units continue uninterrupted operation, making them ideal for long-term or continuous fed-batch operations. |

| During a single run, a single SIPTube® valve can be used to feed in media, to inoculate seed, and to feed acids, bases and nutrients. This multi-functional nature makes the

SIPTube® valve ideal for smaller, highly instrumented research installations. |

| Because the SIPTube® valve can be cleaned and sterilized before each sampling episode, and because samples can be drawn from the heart of the process even the first bit of sample material will be pristine, eliminating the need to discard valuable material. |

|

|